Elevate your brand with custom wood stand displays. Discover durable, eco-friendly, and bespoke solutions direct from a commercial bulk factory for your retail needs.

Table of Contents

1. Why Choose Wood for Your Commercial Display Stands?

1.1 Unmatched Aesthetic Appeal and Versatility

1.2 Durability and Longevity for High-Traffic Environments

1.3 Enhancing Brand Perception and Product Value

1.4 Sustainability and Eco-Friendly Branding

2. What Types of Wood Are Used in Display Manufacturing?

3. Exploring Common Styles of Wooden Display Racks

3.1 Countertop Wood Displays

3.2 Floor-Standing Timber Fixtures

3.3 Wall-Mounted and Slatwall Wood Shelving

3.4 Custom and Themed Wooden Merchandising Stands

4. The Customization Process: From Concept to Bulk Production

4.1 Step 1: Design and Conceptualization

4.2 Step 2: Material Selection and Prototyping

4.3 Step 3: Branding and Finishing Touches

4.4 Step 4: Bulk Manufacturing and Quality Control

5. How to Select the Right Commercial Custom Bulk Factory?

5.1 Evaluating Manufacturing Capabilities and Technology

5.2 Assessing Design and Engineering Support

5.3 Inquiring About Supply Chain and Material Sourcing

5.4 Reviewing Portfolio and Case Studies

6. Key Considerations for Your Bulk Wood Display Order

6.1 Understanding Cost Structures and Budgeting

6.2 Lead Times and Production Schedules

6.3 Packaging and Shipping Logistics

Why Choose Wood for Your Commercial Display Stands?

In the competitive world of retail and trade shows, the way you present your products is just as important as the products themselves. Wood stand displays offer a powerful combination of aesthetic appeal, durability, and brand enhancement that sets them apart from materials like plastic or metal. Opting for wooden fixtures is an investment in quality that communicates a specific message to your customers before they even touch a product.

Unmatched Aesthetic Appeal and Versatility

The primary draw of wood is its natural, timeless beauty. The unique grains, textures, and warm tones of wood create an inviting and authentic atmosphere. This versatility allows wooden display racks to seamlessly fit into a wide range of brand identities. A light-colored pine or maple can create a clean, minimalist Scandinavian look, while a dark-stained oak or walnut can evoke a sense of luxury and tradition. For a rustic, farm-to-table feel, reclaimed or rough-hewn timber is perfect. This adaptability ensures that wood can elevate the presentation of any product, from organic foods and handmade crafts to high-end electronics and jewelry.

Durability and Longevity for High-Traffic Environments

Commercial environments demand fixtures that can withstand constant use. Wooden product display stands are exceptionally durable and resilient. Unlike cardboard, which degrades quickly, or acrylic, which can scratch and crack, well-constructed solid wood or high-quality engineered wood displays can last for years. Their sturdiness makes them ideal for holding heavier items and enduring the bumps and knocks of a busy retail floor. This longevity makes them a cost-effective choice in the long run, reducing the need for frequent replacements and maintenance.

Enhancing Brand Perception and Product Value

The material of your display has a subconscious effect on how customers perceive your brand and products. Wood is intrinsically associated with craftsmanship, quality, and authenticity. By choosing wood, you are signaling to your customers that you care about quality down to the smallest detail. This "halo effect" can elevate the perceived value of your merchandise, making a standard product feel more premium. A beautifully crafted custom wood display acts as a silent salesperson, reinforcing your brand's commitment to excellence.

Sustainability and Eco-Friendly Branding

As consumers become more environmentally conscious, sustainable business practices are a significant brand differentiator. Wood, when sourced responsibly from well-managed forests, is a renewable and biodegradable resource. Highlighting your use of eco-friendly materials like bamboo or FSC-certified wood in your displays can resonate deeply with your target audience. It aligns your brand with positive values, demonstrating a commitment to the planet that goes beyond just the products you sell.

What Types of Wood Are Used in Display Manufacturing?

Choosing the right material is crucial for achieving the desired look, function, and budget for your commercial wood display stands. Different woods offer distinct advantages. A knowledgeable factory can guide you toward the best option based on your specific requirements for strength, aesthetics, and cost. Understanding these differences is the first step in the custom design process.

Here is a breakdown of common materials used in creating custom wood display solutions:

| Wood Type | Key Characteristics | Ideal For |

|---|---|---|

| Solid Wood (Oak, Pine, Maple) | Highly durable, premium feel, beautiful natural grain, heavier, higher cost. | Luxury goods, jewelry displays, high-end boutiques, long-term fixtures. |

| Plywood | Strong and stable due to layered construction, resistant to warping, visible layered edge can be a design feature. | Structural components, large floor units, shelving, modern and industrial aesthetics. |

| MDF (Medium-Density Fiberboard) | Very smooth surface ideal for painting and veneers, cost-effective, easy to machine into complex shapes. | Painted displays, displays with intricate CNC-cut logos, large-scale bulk orders where cost is a factor. |

| Bamboo | Highly sustainable and fast-growing, lightweight yet strong, unique and modern appearance. | Eco-conscious brands, health and wellness products, displays requiring a fresh and natural look. |

Exploring Common Styles of Wooden Display Racks

The form of your display must follow its function. Whether you need to catch a customer's eye at the checkout counter or organize an entire product line on the sales floor, there is a style of wood stand display designed for the job. A full-service manufacturer can produce a range of standard styles or engineer a completely unique solution tailored to your products and retail space.

Countertop Wood Displays

Positioned in high-visibility areas like checkout counters and service desks, countertop displays are perfect for encouraging impulse buys and showcasing smaller items. These can range from simple tiered risers for cosmetics and confectionery to slotted stands for brochures and gift cards. A well-designed wooden countertop unit draws attention without cluttering the space, providing a final, tactile brand touchpoint before a purchase is made.

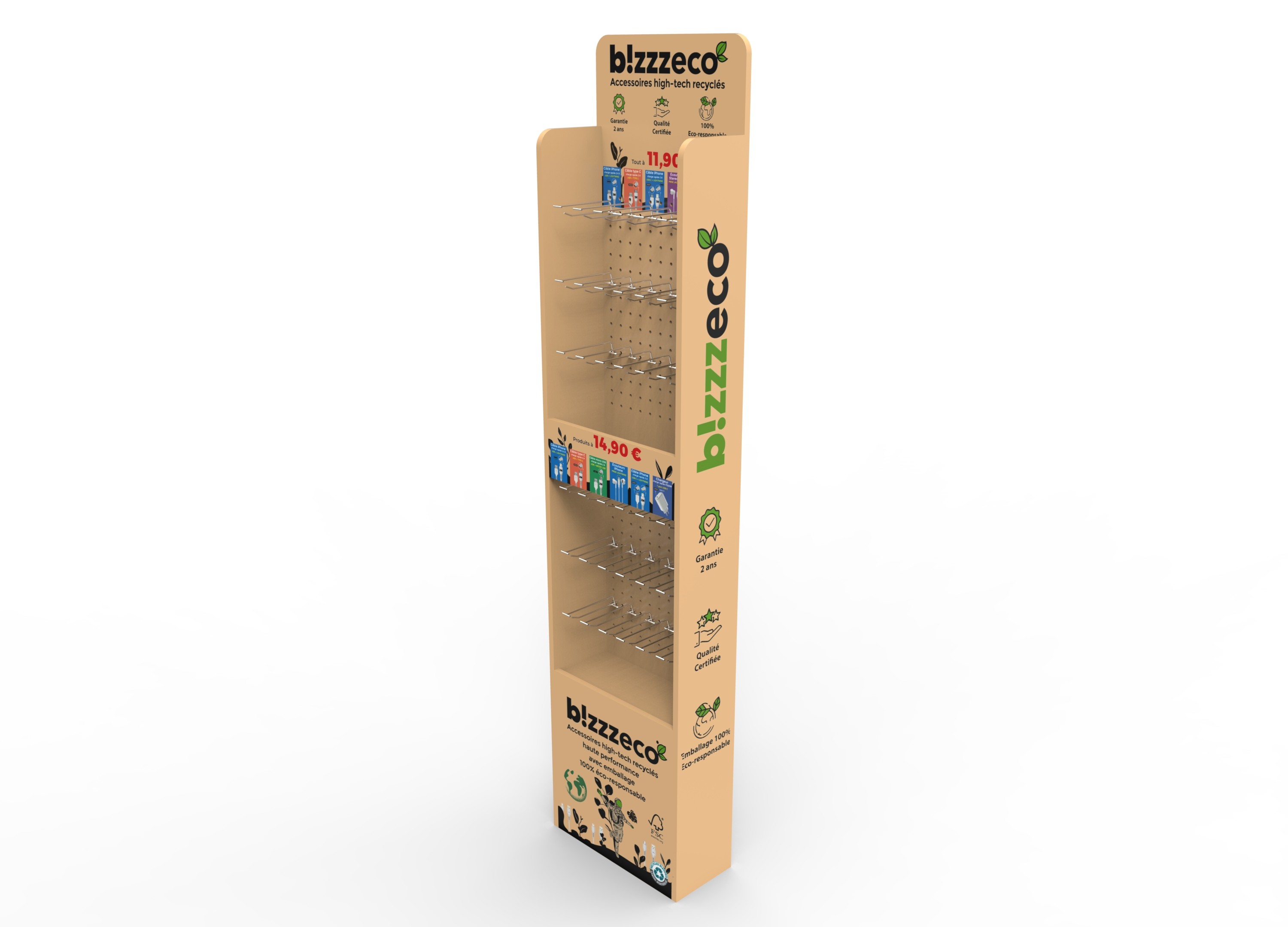

Floor-Standing Timber Fixtures

For larger merchandise or creating a dedicated brand zone within a store, floor-standing fixtures are essential. This category includes multi-shelf gondolas, A-frame easel stands, tiered tables, and "waterfall" racks for apparel. Floor-standing timber fixtures are the workhorses of retail merchandising, defining traffic flow and creating impactful visual statements. Their size allows for significant branding opportunities, such as engraved headers or printed side panels.

Wall-Mounted and Slatwall Wood Shelving

Maximizing vertical space is key to an efficient retail layout. Wall-mounted wood shelving and wood accessories for slatwall systems offer a flexible and scalable solution. They can be used to create an entire feature wall or to add display capacity in tight spaces. These systems are modular, allowing retailers to easily reconfigure shelving to accommodate changing product sizes and seasonal promotions, all while maintaining a cohesive and upscale wooden aesthetic.

Custom and Themed Wooden Merchandising Stands

This is where creativity meets function. A custom wood display factory can bring nearly any concept to life. Imagine a display shaped like your product, a stand that incorporates interactive elements, or a themed fixture for a seasonal campaign. Companies like Rieca Display specialize in this bespoke process, working with brands to develop unique fixtures that are not just product holders but true retail experiences. From wine barrel displays for a vineyard to tree-shaped racks for a bookstore, the possibilities are limited only by imagination.

The Customization Process: From Concept to Bulk Production

Transforming an idea into thousands of finished units requires a structured and collaborative process. Working directly with a custom wood display factory streamlines this journey, ensuring quality control and communication at every stage. This end-to-end approach guarantees that the final product perfectly aligns with your brand's vision and functional needs.

Step 1: Design and Conceptualization

The process begins with your vision. This involves defining the display's purpose, the products it will hold, the target environment, and your brand's aesthetic. You can provide initial sketches, inspiration images, or simply a set of requirements. The factory's design team then translates these ideas into professional 3D renderings and technical drawings. This collaborative stage ensures all functional and visual aspects are perfected before any physical work begins.

Step 2: Material Selection and Prototyping

Once the design is approved, the focus shifts to materials. Based on the design, budget, and durability requirements, the ideal wood and finish are selected. The next critical step is creating a physical prototype. This sample allows you to see and feel the display, test its stability with your products, and approve the color and finish. Manufacturing partners like Rieca Display excel at rapid prototyping, enabling you to make final adjustments and sign off with confidence before committing to a bulk wood retail displays order.

Step 3: Branding and Finishing Touches

A custom display is a powerful branding tool. During this stage, branding elements are integrated into the design. This can include laser engraving a logo, applying a full-color printed graphic, or using CNC routing to cut out lettering. The choice of finish is also finalized, whether it's a clear protective coat to highlight the natural grain, a custom-matched stain to align with brand colors, or an opaque paint for a bold, modern look. These details are what make the display uniquely yours.

Step 4: Bulk Manufacturing and Quality Control

With the prototype approved, the factory gears up for full-scale production. Raw timber is cut, machined, finished, and assembled according to the precise specifications. A key advantage of working with a direct manufacturer is their rigorous quality control. Inspections are performed throughout the production line—from material integrity to final assembly—to ensure that every single unit in your bulk order is consistent and meets the approved standard. This eliminates inconsistencies and guarantees a professional result across your entire retail network.

How to Select the Right Commercial Custom Bulk Factory?

Your choice of manufacturing partner will have the biggest impact on the quality, cost, and timeliness of your project. Not all factories are created equal. Due diligence is essential to find a partner that can act as an extension of your team and reliably deliver on your vision.

Evaluating Manufacturing Capabilities and Technology

Look for a factory with a comprehensive set of in-house capabilities. Do they have modern equipment like CNC routers, laser cutters and engravers, and a professional finishing department? A factory that controls the entire production process under one roof can offer better quality control, faster lead times, and more competitive pricing. Ask about their capacity to handle the volume of your order without compromising on quality.

Assessing Design and Engineering Support

A great factory does more than just manufacture; they provide solutions. Look for a partner with a strong in-house design and engineering team. Can they help refine your concept for better functionality or cost-effectiveness? Expert partners such as Rieca Display offer this crucial value-add, providing technical guidance to ensure your display is not only beautiful but also stable, shippable, and easy to assemble. This expertise is invaluable, especially for complex or innovative designs.

Inquiring About Supply Chain and Material Sourcing

Ask potential partners about their material sourcing. Where do they get their wood? Can they provide documentation for sustainable sourcing, such as FSC or PEFC certification? A transparent and ethical supply chain is a mark of a reputable company. It also ensures material quality and consistency, which is vital for large production runs of wholesale wood displays.

Reviewing Portfolio and Case Studies

The best indicator of future performance is past work. Ask to see a portfolio of projects they have completed, paying close attention to examples that are similar to yours in complexity, material, or industry. Case studies and testimonials from other businesses provide real-world proof of their ability to deliver high-quality products and manage projects effectively. A confident manufacturer will be proud to share their successes.

Key Considerations for Your Bulk Wood Display Order

Beyond design and manufacturing, the logistics and finances of a bulk order require careful planning. Addressing these points early in the process will ensure a smooth project from start to finish, with no surprises along the way.

Understanding Cost Structures and Budgeting

When requesting a quote for a bulk wood retail displays order, be sure you understand all the cost components. The unit price will typically decrease as the order quantity increases. However, inquire about one-time costs such as design fees, prototype development, and tooling or setup charges. A transparent quote should break down these elements clearly, along with the per-unit cost, allowing you to build an accurate budget for the project.

Lead Times and Production Schedules

"How long will it take?" is a critical question. The total lead time includes design, prototyping, production, and shipping. Be sure to communicate your desired in-store date to the factory upfront. A reliable manufacturer will provide a realistic production schedule and keep you updated on progress. Factor in potential delays and build a buffer into your project timeline, especially for large or complex orders.

Packaging and Shipping Logistics

How the displays are packaged and shipped is crucial to ensuring they arrive at their destination safely and ready for assembly. Discuss packaging options with your factory. Should displays be shipped fully assembled or flat-packed to save on freight costs and reduce the risk of damage? If shipping flat, are the assembly instructions clear and simple? Experienced manufacturers, particularly those like Rieca Display with global shipping experience, can engineer packaging solutions that protect the product while optimizing logistics for cost and efficiency.