Source high-quality horizontal shelf dividers for export directly from Indian manufacturers, ensuring cost-effectiveness, customization, and superior quality.

Table of Contents

- Understanding the Role of Horizontal Shelf Dividers in Retail

- What are the Strategic Advantages of Sourcing Dividers from India?

- How to Select the Right Direct Manufacturer for Shelf Dividers in India

- Exploring Material and Design Variations for Export

- What is the Process for Customizing Horizontal Shelf Dividers (OEM/ODM)?

- Navigating the Export and Shipping Process from India

Horizontal Shelf Dividers India Export: A Manufacturer Direct Sourcing Guide

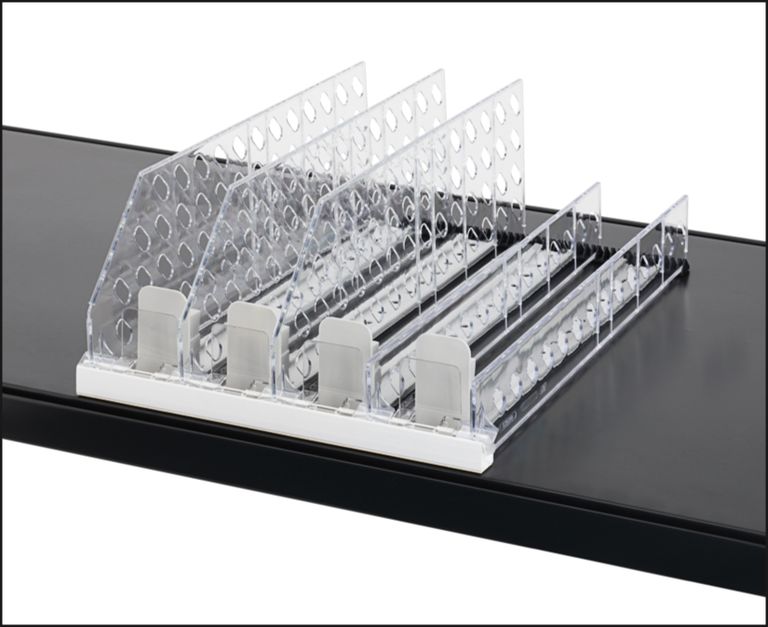

In the competitive world of retail, product presentation and organization are paramount. Horizontal shelf dividers, also known as shelf separators or product organizers, are essential tools for creating a clean, structured, and easy-to-navigate shopping experience. For international businesses looking to procure these vital components, sourcing them directly from a manufacturer in India offers significant benefits. Partnering with an experienced Original Equipment Manufacturer (OEM) provides access to cost-efficient production, extensive customization, and a streamlined export process, ensuring you receive a product perfectly tailored to your retail environment.

Understanding the Role of Horizontal Shelf Dividers in Retail

Horizontal shelf dividers are more than just plastic or metal partitions; they are a fundamental part of an effective shelf management system. Their primary function is to neatly segment products on a shelf, preventing items from toppling over, mixing, or appearing cluttered. This organization directly impacts customer behavior and operational efficiency. When products are clearly delineated, shoppers can easily find, compare, and select items, which improves their overall experience and can lead to increased sales. A well-organized shelf appears fuller and more appealing, projecting an image of professionalism and abundance.

From an operational standpoint, these dividers are invaluable. They simplify the restocking process, as staff can quickly see which products need replenishment and place them in their designated spots. This reduces labor time and minimizes stocking errors. Furthermore, effective shelf management maintains planogram integrity, ensuring that promotional items and high-margin products are displayed exactly as intended to maximize visibility and impact. By maintaining order, dividers also help in accurate inventory tracking, reducing shrinkage and ensuring the right amount of stock is on the shelf at all times.

What are the Strategic Advantages of Sourcing Dividers from India?

India has emerged as a global manufacturing hub, particularly for retail fixtures and point-of-purchase (POP) solutions. Choosing to source horizontal shelf dividers directly from an Indian manufacturer presents several strategic advantages for international businesses. The most significant benefit is cost-effectiveness. Lower operational and labor costs in India translate into competitive pricing without compromising on quality, allowing businesses to procure high-volume orders at a fraction of the cost compared to Western markets.

Beyond price, Indian manufacturers are renowned for their robust production capabilities and focus on quality. Companies like Rieca Display exemplify this, operating as dedicated OEM/ODM partners. This direct-from-manufacturer model eliminates intermediaries, leading to better communication, faster turnaround times, and greater control over the final product. You work directly with the team that designs and creates your dividers. Additionally, India's manufacturing sector is known for its skilled workforce and adaptability, offering extensive customization options in terms of material, size, color, and branding. This flexibility ensures the final product aligns perfectly with your specific retail needs and brand identity.

How to Select the Right Direct Manufacturer for Shelf Dividers in India

Choosing the right manufacturing partner is critical to a successful sourcing strategy. When evaluating potential suppliers for horizontal shelf dividers, it is essential to look beyond the price tag and assess their holistic capabilities. A reliable partner acts as an extension of your team, providing expertise, quality assurance, and dependable logistics. The goal is to find a manufacturer with a proven track record of producing high-quality retail fixtures for a global clientele.

Verify Manufacturing Capabilities and Technology

A premier manufacturer should possess advanced technology and a well-equipped facility. Inquire about their machinery, production capacity, and the materials they work with. Do they have experience with injection molding, extrusion, and fabrication for plastics like PVC, acrylic, and PETG? An established OEM/ODM specialist will have a dedicated engineering and design team that can assist with product development, from initial concept to final prototype. Their ability to create custom molds and tooling is a strong indicator of their technical expertise and commitment to delivering tailored solutions.

Assess Quality Control and Material Standards

Quality assurance is non-negotiable. Ask potential manufacturers about their quality control (QC) processes. A trustworthy company will have a multi-stage QC protocol that includes raw material inspection, in-process checks, and a final inspection of the finished goods before shipment. They should be transparent about the grade and origin of their materials, ensuring they are durable, clear, and meet international standards. Requesting samples is an excellent way to physically evaluate the product's finish, sturdiness, and overall craftsmanship before committing to a large order.

Evaluate Export Experience and Logistics

Exporting from India involves specific documentation, packaging standards, and logistics coordination. A partner with extensive export experience is invaluable. They will be well-versed in managing international shipping, handling customs clearance, and ensuring your products are packaged securely to prevent damage during transit. Companies with a history of exporting to various continents, including North America, Europe, and the Middle East, demonstrate their capability to meet diverse regulatory requirements and deliver on time. This experience minimizes potential delays and ensures a smooth, hassle-free procurement process from factory to warehouse.

Exploring Material and Design Variations for Export

The effectiveness of a horizontal shelf divider depends heavily on its material and design. A direct manufacturer in India can offer a wide array of options to suit different product types, shelf surfaces, and aesthetic preferences. Working with an OEM/ODM partner like Rieca Display allows you to specify the exact features you need rather than settling for a standard, off-the-shelf product.

Common Materials: PVC, Acrylic, and PETG

The choice of material impacts the divider's durability, clarity, and cost. Each has distinct properties suitable for different retail environments.

| Material | Key Characteristics | Best For |

|---|---|---|

| PVC (Polyvinyl Chloride) | Highly durable, cost-effective, and flexible. Resistant to impact and moisture. | High-traffic environments like supermarkets, hardware stores, and discount retailers. |

| Acrylic (PMMA) | Offers superior clarity and a premium, glass-like appearance. More rigid than PVC. | Upscale retail, cosmetics counters, boutiques, and electronics stores where aesthetics are crucial. |

| PETG (Polyethylene Terephthalate Glycol) | Combines the clarity of acrylic with the durability of PVC. FDA-compliant and impact-resistant. | Pharmacies, food aisles, and any application requiring high strength and food-safe properties. |

Functional Designs: T-Style, L-Style, and Magnetic Bases

The design of the divider's base determines how it attaches to the shelf. The most common designs include T-style dividers, which slide into a front or back rail system, offering easy adjustability. L-style dividers, on the other hand, typically adhere directly to the shelf surface using double-sided tape or rest freely, making them versatile for solid shelving. For metal shelves, magnetic base dividers provide a strong, secure hold that is still simple to reposition without leaving residue. The height, length, and thickness of the divider can also be fully customized to accommodate products ranging from small cosmetic boxes to larger grocery items.

What is the Process for Customizing Horizontal Shelf Dividers (OEM/ODM)?

One of the primary reasons to work with a manufacturer direct is the ability to fully customize the product. The OEM/ODM process is a collaborative journey to create a horizontal shelf divider that meets your exact specifications. It begins with an initial consultation where you discuss your requirements, including dimensions, material, design, and any branding elements like color matching or logo printing.

Following this, the manufacturer's design and engineering team will create technical drawings and, in many cases, a 3D rendering for your approval. This stage allows for refinements before any physical production begins. Once the design is finalized, a prototype or first-article sample is produced. This tangible sample allows you to test the divider in your actual retail environment to ensure it fits, functions, and looks as expected. After your approval of the sample, mass production commences under strict quality control. This structured process, managed by an experienced team, guarantees that the final shipment of dividers aligns perfectly with your vision and functional needs.

Navigating the Export and Shipping Process from India

For many businesses, the prospect of international logistics can seem daunting. However, when you partner with an experienced Indian exporter, the process becomes remarkably straightforward. A seasoned manufacturer handles all the critical aspects of getting your order from their factory floor to your destination port or warehouse. Their expertise begins with professional-grade packaging. Horizontal shelf dividers are carefully bundled, protected, and packed into master cartons designed to withstand the rigors of long-distance sea or air freight, minimizing the risk of breakage.

The manufacturer's logistics team will then manage all necessary export documentation, including the commercial invoice, packing list, bill of lading, and certificate of origin. They coordinate with freight forwarders to book container space and manage the shipment's journey. By handling these complexities, they provide a seamless, end-to-end service. This allows your team to focus on your core business, confident that your custom-manufactured shelf dividers will be delivered safely, on schedule, and in compliance with all international trade regulations. This logistical proficiency is a hallmark of a top-tier manufacturing partner.